1. Introduction

The Design Activities Confirmation (DAC) is a document that outlines a tool’s scope of work. It is a comprehensive guide for Engineers, enabling them to clearly align their work scope and allocate resources effectively to achieve project objectives. The AE Engineer creates the DAC and assigns it to the Tool Owner/Area Coordinator, who completes the form by verifying that all design activities related to the tool have been adequately addressed. Afterwards, the completed DAC is reviewed by the AE Design Lead for final validation.

RP and TD focus on innovation, developing new technologies, and optimising processes, necessitating a DAC form that emphasises design readiness for groundbreaking tools and technologies. The RP DAC is not needed before the TD DAC. In HVM, the emphasis shifts to mass production efficiency, scalability, and quality, requiring a DAC form that ensures designs are innovative but also practical and reliable for high-volume manufacturing. This differentiation ensures that the DAC effectively addresses the unique challenges and checkpoints relevant to each phase.

2. Workflow

The workflow for RP, TD, and HVM sites follows the same process, with one key distinction: the RP version includes an automation process. See below for the process flows.

For the initial revision created in LSPx (typically Revision 0), the RP DAC must be manually generated. However, once subsequent revisions (Revision 1 and beyond) are added to the RP Schedule, the RP DAC is automatically created and immediately sent to the Tool Owner for further action.

You can manually create the first RP DAC in LSPx for new revisions issued on or after the release date (April 16, 2025). All existing DAC revisions before this feature release are labelled with “NO DAC in LSPx” status. Once the first DAC is created, subsequent RP DACs will be automatically generated without manual intervention. For existing revisions that do not have a DAC before the release date, the first DAC created in LSPx will be considered the first and display the Tool Go-By field.

2.1. RP

2.2. TD and HVM

2.2. Process / User Journey

The table below encompasses the five DAC statuses, the company responsible for taking it to the next stage and the action buttons you will see in the application (if you have the appropriate role permissions):

| Step/Description | Current Status | Task Owner | Action Buttons | New Status | |

|---|---|---|---|---|---|

| 1 | DAC is created by users of an AE Firm and sent to the Tool Owner (TO) for completion. * For the RP DAC, this step can be automatically created by the system depending on the revision. | AE DRAFT | AE FIRM | SEND TO TOOL OWNER | DAC CREATED |

| 2 | Any of the Tool Owners (TO) or Area Coordinators (AC) associated with the tool can respond to DAC. | DAC CREATED | INTEL | SEND TO AE | TOOL OWNER REVIEWED |

| 3 | If there are any issues, the AE Firm can return the DAC back to the Tool Owner or Area Coordinator to rectify. If the AE Firm is satisfied with the information on the DAC, they close the DAC. | TOOL OWNER REVIEWED | AE FIRM | RETURN TO TOOL OWNER REVIEW TO CLOSE | RETURNED TO TOOL OWNER CLOSED |

| 4 | If the AE Firm returns the DAC, it will need to be updated by the Tool Owner or Area Coordinator. | RETURNED TO TOOL OWNER | INTEL | SEND TO AE | TOOL OWNER REVIEWED |

| 5 | The AE Firm assigned to the tool can reopen a DAC after it has been closed. | CLOSED | AE FIRM | REOPEN | RETURNED TO TOOL OWNER |

The DAC can either be invalidated or deleted depending on their type:

- RP DAC: Can be either invalidated or deleted.

- TD/HVM DAC: Can only be deleted.

Invalidation

- If a DAC is invalidated, its status will change to INVALID.

- The DAC remains in the system but will no longer be active.

Deletion

- If a DAC is deleted, it is permanently removed from the system.

- A new DAC must be created to replace the deleted one.

- This action is irreversible.

Whenever a DAC is invalidated or deleted, an email notification will be sent to all users associated with the DAC.

3. Email Notifications

Based on the DAC status, the following users will receive email notifications when there are changes:

- AE users of the company assigned to the tool

- Tool Owners that appear on the Stakeholders

- Area Coordinators that appear on the Stakeholders

- The Watchers added to the DAC

Users with the Tool Install "Design Manager" role can create, read, update, and delete the DAC for their project. However, they will not receive email notifications. The Integration users have a read-only access to view the DAC.

4. Creating the DAC

The fields available on the DAC form in LSPx will vary by project, based on whether it is classified as Reference Package (RP), Tool Design (TD) or High-Volume Manufacturing (HVM). Additionally, for TD and HVM, the fields displayed will depend on the Tool Event Type [Install, Demo, or Convert in Place (CIP)]. Watch the Training Videos for how to create, submit and complete DACs in the LSPx application. The table below outlines the fields available on the DAC in LSPx.

4.1. AE Firm Details - Create DAC

| RP, TD or HVM | Tool Event Type | Field Name in LSPx | Mandatory or Optional | Notes | |

|---|---|---|---|---|---|

| 1 | RP TD HVM | Install Demo CIP | Entity Code - Life | Automatically populated | The DAC is embedded within the Tool Details page, so you must select a tool before accessing it. To ensure you are on the correct tool, look for the Entity Code - Life to the top left of your screen.  |

| 2 | RP TD HVM | Install Demo CIP | Tool Details | Automatically populated | Information about the tool can be found next to the Entity Code - Life on the Tool Details page.  |

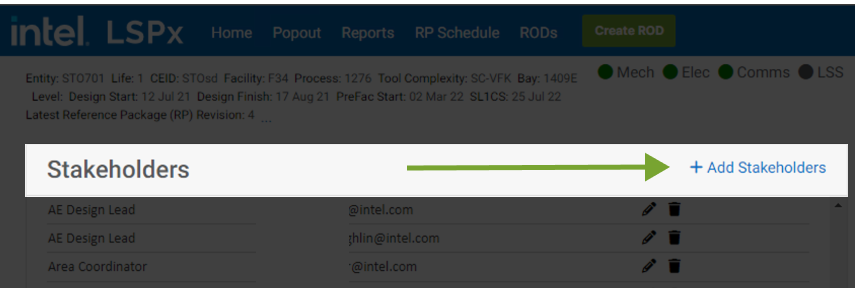

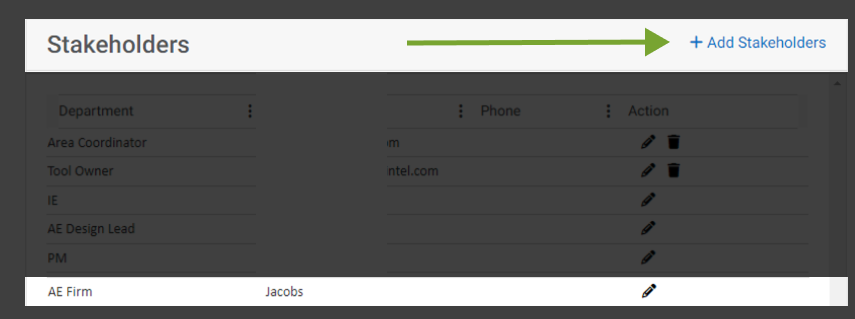

| 3 | RP TD HVM | Install Demo CIP | AE Firm | Automatically populated | If the AE Firm or other users that automatically appear on the DAC are incorrect, they can be updated in the Stakeholder component of the Tool Details page. The AE Design Leads, AE Administrators and Stakeholder Admin can add/remove people and companies. The Area Coordinator can only add/remove the Tool Owners and other Area Coordinators on the tool.  |

| 4 | RP TD HVM | Install Demo CIP | AE Design Lead | Automatically populated | If the AE Design Leads are incorrect, they can be updated in the Stakeholder component of the Tool Details page. |

| 5 | RP TD HVM | Install Demo CIP | Tool Owner | Automatically populated | If the Tool Owners are incorrect, they can be updated in the Stakeholder component of the Tool Details page. |

| 6 | RP TD HVM | Install Demo CIP | Area Coordinator | Automatically populated | If the Area Coordinators incorrect, they can be updated in the Stakeholder component of the Tool Details page. |

| 7 | RP TD HVM | Install Demo CIP | Description | Optional | The “Description“ field is a rich text editor that allows you to add text, links, images, and other web components. |

| 8 | RP TD HVM | Install Demo CIP | DAC Return Due Date | Automatically populated | The DAC Return Due Date varies between projects. The DAC must be closed by this date. It is automatically set to x working days before the Pedestal Design Start or Tool Install Design Start Date. Learn more about the number of days for each site. |

| 10 | RP TD HVM | Install Demo CIP | Design Start | Automatically populated | The Design Start date from the POR Schedule. |

| 11 | RP TD HVM | Install Demo CIP | Watchers | Optional | Any user with an LSPx account on the site can be added here to receive email notifications about the DAC. |

| 12 | RP TD HVM | Install Demo CIP | Attachment | Optional | Supported file types are: • "doc", "docx", "txt", "pdf", "csv", "xlsx", "xml", "xltx", "jpg", "jpeg", "png", "dwg", "msg", "dwf", "nwd", "eml" |

4.2. Tool Owner Details - Provide Tool Information

| TD or HVM | Tool Event Type | Field Name in LSPx | Mandatory or Optional | Notes | |

|---|---|---|---|---|---|

| 13 | RP | N/A | RP Revision Number | Automatically populated | This is automatically populated for each revision. One DAC can be created for each revision on an RP DAC. |

| 14 | TD HVM | Install Demo CIP | Tool Event Type | Automatically populated | The Event Type is automatically populated from the POR Schedule. If it is incorrect, you can change it by selecting the "Different to POR Schedule?" checkbox. This will display a dropdown menu allowing you to choose the correct Event Type. Changing the Event Type will update the fields available for submission on the DAC form. Learn more about the Tool Event Type |

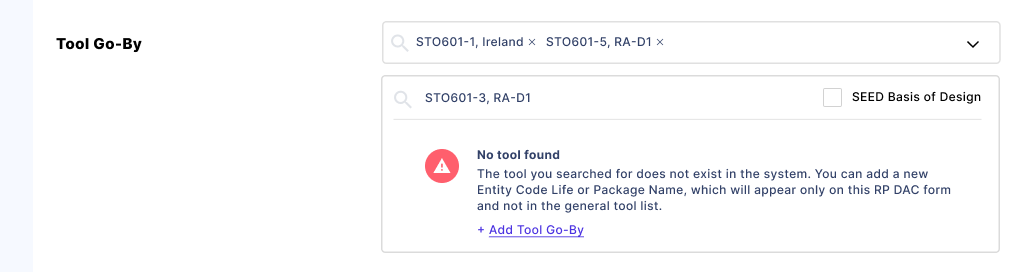

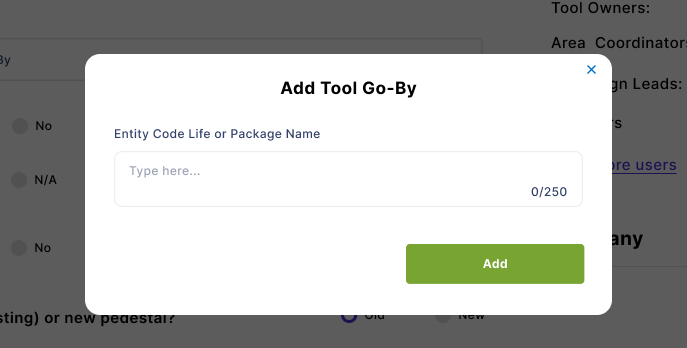

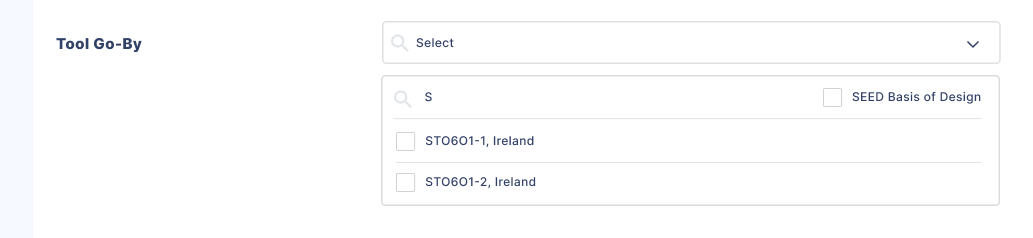

| 15 | RP TD HVM | Install Demo CIP | Tool Go-By | Mandatory | The Tool Go-By is a multi-select field where you can choose tools from all sites on the TD/HVM DAC. For the RP DAC, you can only choose tools from Oregon. NOTE: The POR Schedule [ODS Table] is the true source of data for tools in-flight. However, for RP DAC, if the tool required is not listed, you can add Entity Code Life or Package Name" under the Tool Go-By. You will then need to provide mandatory information about the new tool.   |

| 16 | RP TD | Install | SEED Basis of Design • BIM360 Link | Optional | If the Tool Go-By is a “SEED Basis of Design” and the checkbox is ticked, then the “Tool Go-By” field is optional. The “BIM360 Link” field will appear if the “SEED Basis of Design” is ticked and providing the BIM360 link is completely optional.   |

| 17 | RP | N/A | Main Tool SEED Update? | Mandatory | The "Main Tool SEED Update?" question have two radio button options: • Required • Received |

| 18 | RP | N/A | Sub-supplier SEED Update? | Mandatory | The "Sub-supplier SEED Update?" question have two radio button options: • Required • Received |

| 19 | HVM | Install Demo CIP | Basis of Design Type | Manadatory | This is a single-select field where you can choose from the available options. |

| 20 | HVM | Install Demo CIP | RP/Goby CEID File Name | Mandatory | This is a free-text field and you can provide any information including BIM360 (RP Folder) links where the files are stored. |

| 21 | HVM | Install Demo CIP | Go-By Decoder Updated? | Optional | The “Go-By Decoder Updated?” field is available on the three HVM DAC forms. There is a default selection of No but it is still an optional field. It has two options: • Yes • No |

| 22 | TD HVM | Install | Go/No/Go (GNG) Meeting | Mandatory | The "Go/No/Go (GNG) Meeting" field have two radio button options: • Yes • No The default value of this field on the TD sites is "Yes". This is because there's usually a GNG meeting. However, Tool Owners and Area Coordinators can opt to bypass the GNG meeting if scope has been clearly defined in the DAC. |

| 23 | TD HVM | Install | Pedestal | Mandatory | The “Pedestal” field have three radio button options: • Yes • No • Selecting “Yes” displays two options: “Reuse” and “New”. -- Selecting “Reuse” requires you to “Provide additional information about the old pedestal”, which is mandatory to complete. -- Selecting “Reuse” or “New“ requires you to confirm whether the "Pedestal Exclusion Zone (PEZ)" has been reviewed. (Yes or No). • Selecting No does not require any additional information on the Pedestal. • You can choose Unknown if you are unsure but be aware that the AE approver could reject the DAC for this reason. |

| 24 | HVM | Install Demo CIP | Pedestal Go-By | Mandatory/Optional | This is a dropdown field connected to the Tool database and display tools for all sites. • If you selects "Yes" on Pedestal, the "Pedestal Go-By" becomes mandatory. • Selecting "No" or "Unknown" will not display the field. |

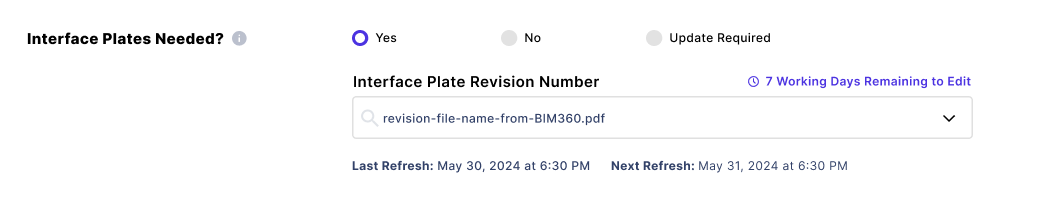

| 25 | RP TD HVM | Install | Interface Plates Needed? • Interface Plate Revision Number | Mandatory | The "Interface Plates Needed?" field have two or three radio button options depending on the site: • Selecting “Yes” requires you to provide if there is a need for a “New Interface Plate Design Required?” with (Yes/No) options. - This option will require you to provide the one "Interface Plate Revision Number" pdf file from the dropdown. • Selecting "No" for the "Interface Plates Needed?", will not require further questions. • Selecting "Update Required" for the "Interface Plates Needed?", will not require further questions.  On the TD/HVM DACs, you will automatically see the latest revision file name (from BIM360) in the "Interface Plates Needed?" question. The Tool Owner / Area Coordinator will have five (5) working days to change this field before it is locked. Otherwise, a DCR will need to be raised. This does not apply to the RP DAC. NOTE: The date below the "Interface Plates Needed?" displays the date of last and next time the file list was updated from BIM360. |

| 26 | HVM | Install | IE Review | Mandatory | The "IE Review" is to confirm if the desktop review been completed and approved with the IE and Tool Owner. There are two radio button options: • Yes • No |

| 27 | HVM | Install | Cleanroom Style | Optional | The “Cleanroom Style” field have three radio button options: • Bay/Chase/Room • Flow Thru/Ball Room • None |

| 28 | RP TD HVM | Install Demo CIP | Additional Scope Comments | Optional | The “Additional Scope Comments“ field is a rich text editor that allows you to add text, links, images, and other web components. |

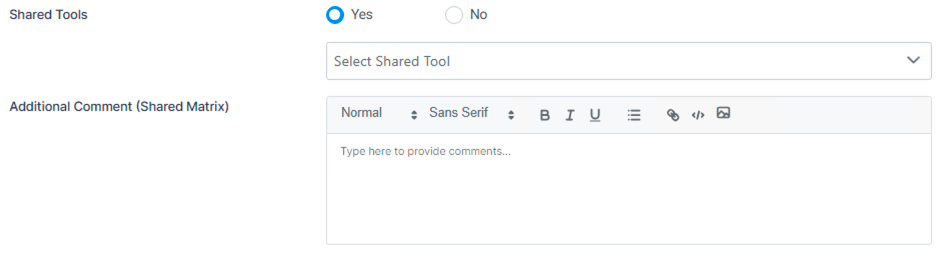

| 29 | HVM | Install | Shared Tools • Shared Tools • Additional Comment (Shared Matrix) | Mandatory | The “Shared Tools” field have two radio button options: • Choosing Yes will require you to select at least one tool from the dropdown list and provide "Additional Comment (Shared Matrix) in the field below. • No is the default selection  |

| 30 | HVM | Install | Safety Shower/Eye | Optional | The “Safety Shower/Eye” field have two radio button options: • Yes • No |

| 31 | TD | Install | New Supplier Data | Mandatory | TICE Design uses the “New Supplier Data” information to verify Complexity/Type column in POR and assign design resources. There are two radio button options: • Yes is the default selection when SEED Basis of Design is selected • No |

| 32 | TD | Install | New CEID Config | Mandatory | TICE Design uses the “New CEID Config” information to verify Complexity/Type column in POR and assign design resources. There are two radio button options: • Yes is the default selection when SEED Basis of Design is selected • No |

| 33 | TD | Install | Tool Config Frozen | Mandatory | TICE Design uses the “Tool Config Frozen” information to indicate potential scope changes during design. There are two radio button options: • Yes • No |

| 34 | TD HVM | Install | Difference Form Required? | Optional | The “Difference Form Required?” field have two radio button options: • Yes is the default selection for HVM sites • No is the default selection for TD sites |

| 35 | HVM | Install | Cover Plates Design Required? | Optional | The “Cover Plates Design Required?” field have two radio button options: • Yes • No |

| 36 | HVM | Install | LSS Scope | Optional | The “LSS Scope” field have two radio button options: • Yes means the the Tool Owner / Area Coordinator knows the Model Of Record (MOR) and Layout (LO) of LSS components. AEs are not LSS Scope experts. • No |

| 37 | TD HVM | Demo | Vendor Supplied Interface Plate? | Mandatory | The “Vendor Supplied Interface Plates” field have two radio button options: • Yes • No |

| 38 | TD HVM | Demo | Type of Demo | Mandatory | The “Type of Demo” field have two radio button options: • Full • Partial |

| 39 | TD HVM | Demo | Scrap or Reuse | Optional | The “Scrap or Reuse“ field is a rich text editor that allows you to add text, links, images, and other web components. |

| 40 | TD HVM | Demo | Reuse Vendor Cables | Mandatory | The “Reuse Vendor Cables” field have two radio button options: • Yes • No |

| 41 | TD HVM | Demo | Pedestal Cover Plates Required | Mandatory | The “Pedestal Cover Plates Required” field have two radio button options: • Yes • No |

| 42 | TD | Convert in Place | SEED Updates Coming/Planned? | Mandatory | The “SEED Updates Coming/Planned?” field have two radio button options: • Yes • No |

| 43 | TD | Convert in Place | Layout (LO) Scope | Mandatory | The “Layout (LO) Scope” field have two radio button options: • Yes • No |

5. People, Company and Dates

The table below provides additional information about the People, Company and Dates that you see on the DAC form. Update refers to Edit and Transitioning of the DAC.

| Role | Role Description | Create | Read | Update | Delete | |

|---|---|---|---|---|---|---|

| 1 | Tool Owner | The Tool Owners assigned to the tool to oversee the functionality and maintenance. They ensure these tools operate efficiently, meet production requirements, and maintain high-quality standards. | ❌ | ✅ | ✅ | ✅ |

| 2 | Area Coordinator | The Area Coordinators assigned to the tool to manage and oversee specific areas within the manufacturing process on a site. They coordinate activities, ensure production goals and quality standards are met, and facilitate communication between different teams. | ❌ | ✅ | ✅ | ✅ |

| 3 | AE Firm | The AE Design Lead oversees and guides a project's architectural and engineering design aspects. There other AE roles with interest in the DAC but the AE Design Lead is the only AE representative that appears on the DAC form. The other AE roles also have the same permission levels as the AE Design Lead. Although AEs cannot delete the DAC once sent to the Tool Owner, they can delete the draft they create. | ✅ | ✅ | ✅ | ❌ |

| 4 | Watchers | Users who are not added automatically but are manually included for DAC awareness | ❌ | ✅ | ❌ | ❌ |

| 5 | Tool Install Design Managers | The Design Managers on the project does not appear on the DAC form but has full autonomy to control the DAC in LSPx. They are not notified on changes to the DAC via email. | ✅ | ✅ | ✅ | ✅ |

The AE Firm is the design company assigned to the tool as displayed on the Stakeholders on the Tool Details page. The AE Firm appears under the Company section of the DAC using the data provided from the POR Schedule. If the POR Schedule has any inaccuracies for the AE Firm, the data here will reflect those errors, even if it is manually updated in LSPx. There is an ongoing discussion to implement a new logic that will retain any manual updates in LSPx.

The Reporter and Assignee does not appear in the People section of the DAC. The Reporter can be any user permitted to create the DAC. You can view the DAC History to monitor all events including the person that created the DAC.

| Dates | Description |

|---|---|

| Created | The date the DAC was created (FCEConnect or LSPx). |

| Last Updated | The last time this DAC was updated in (FCEConnect or LSPx). |

| DAC Return Due Date | The DAC must be closed by this date. It is automatically set to x working days prior to the Pedestal Design Start or Tool Install Design Start Date. The earliest of the two dates is used for the calculation. |

| Design Start | The date which the design is expected to start. |

6. Permissions Matrix

6.1. User Interface (UI) Pages

The table below shows the pages or screens on the DAC form and the users involved along with the permissions they have.

| Page | Purpose | Create/Edit | Update | |

|---|---|---|---|---|

| 1 | AE Details | This page is for the AE Firm to kick-off the DAC and send it to the Tool Owner to complete. | AE FIRM | AE FIRM |

| 2 | Tool Owner Details | The Tool Owner and the Area Coordinator will complete this page providing relevant information. For example, whether the tool will use an existing or new pedestal. Upon completion, they will send it to the AE Design Lead for review. | TOOL OWNERS AREA COORDINATORS | TOOL OWNERS AREA COORDINATORS |

| 3 | AE Review | The AE Design Lead will review the provided information. They can close the DAC or send it back to the Tool Owner for amendments. | N/A | AE FIRM |

6.2. Stakeholder Master

LSPx seamlessly integrates with Stakeholder Master (FCEHome) to automatically synchronise changes in either applications. Suppose a stakeholder's details is not auto-populated on a DAC form; permitted users can update the information from the Stakeholder component on the Tool Details page. Changes from the Stakeholder component on the Tool Details synchronises back to the Stakeholder Matrix (FCEHome).

Using the "Add Stakeholders" or edit functionality:

- The AE Administrator and Stakeholder Admin roles can update the companies and users.

- The Area Coordinator role can update only the Tool Owners and Area Coordinators.

- The Tool Owner role can only add/remove themselves to a tool.

- The Project Manager (PM) role can only add/remove themselves to a tool.

7. DAC Return Due Date Calculation

The DAC Return Due Date is calculated as x working days before the earliest of the Pedestal Design or the Tool Install Design Start Date. The table below shows, for each site, how many working days the DAC must be returned before whichever date occurs first. Public holidays and weekends are considered in the calculation.

| Site | Pedestal Design Start Offset (working days) | Tool Install Design Start Offset (working days) |

|---|---|---|

| Ocotillo | –1 | –25 |

| Santa Clara | –25 | –25 |

| Ireland | –15 | –15 |

| Ronler Acres | –15 | –15 |

| Other Projects | –10 | –10 |

Note: For Ocotillo, when the Pedestal Design Start Date is earlier than the Tool Install Design Start Date, x = –1 working day; otherwise x = –25 working days. Public holidays and weekends are included in all calculations.

8. Tool Event Type

There are multiple tool event types from the POR Schedule. However, there is a mapping in LSPx to categorise them into three main categories [Install, Demo and Convert in Place (CIP)]. The table below shows all the event types from POR and its category in LSPx. To ensure that DACs can be created for all necessary events, below is a simple rule for determining the type:

- If "Install" is in the word, use the Install form.

- If "Demo" is in the word, use the Demo form.

- If "Conv", "Qual/Qual-Fac" or "Upgrade/Upgrade-Fac" is in the word, use Convert in Place (CIP) form. Learn more about the Tool Event Type

9. Important Links/Guides

- Watch the Training Videos for how to create, submit and complete DACs in the LSPx application.

- Learn how to manage Stakeholders in LSPx.

- Frequently Asked Questions for the DAC.